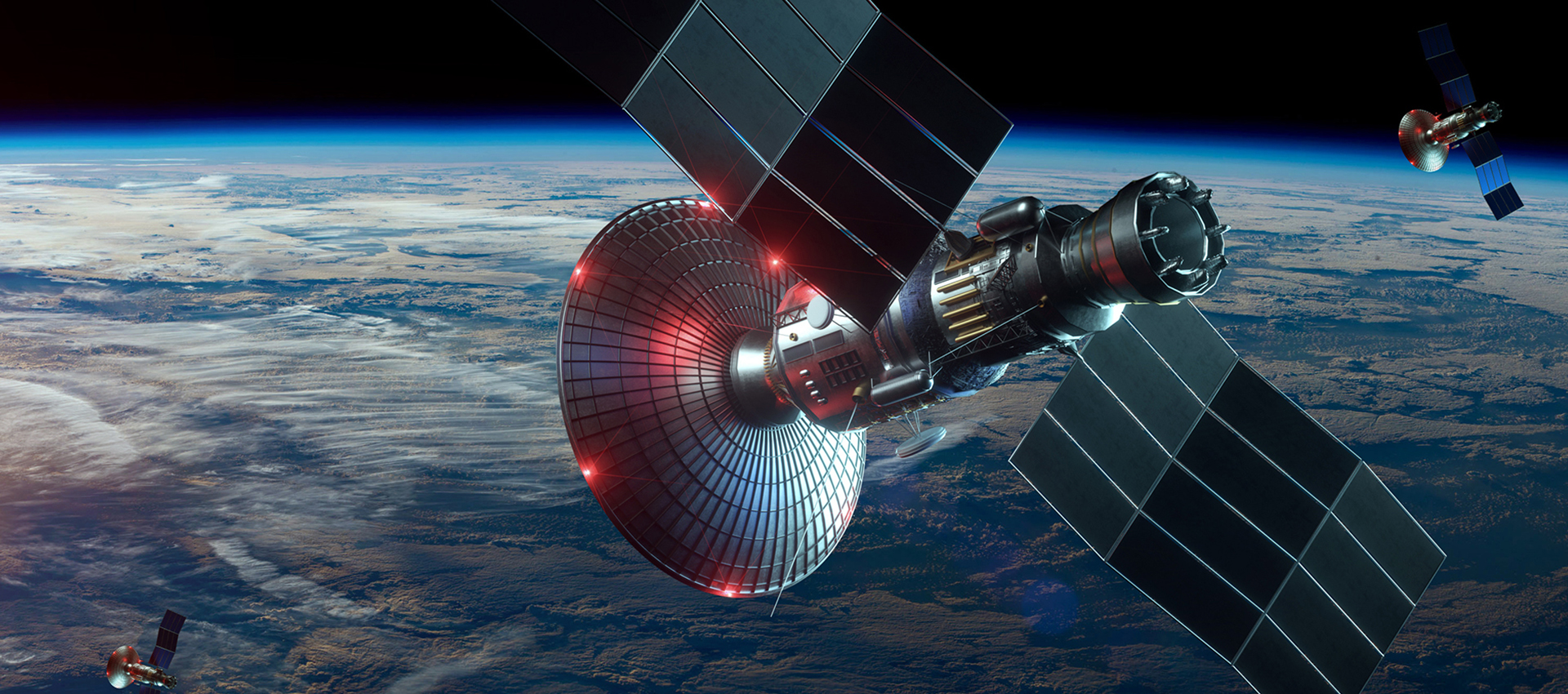

Satellite and Space

Magnesium Alloys in Space Applications

Magnesium alloys have been used in spacecraft for many years due to their unique properties. They are lightweight, strong, and durable, and can withstand the extreme conditions of space.

Magnesium alloys are excellent choices for critical space applications which require low-weight, high-strength, durable, and dimensionally stable materials.

Advantages of magnesium alloys in space applications:

Strength

Magnesium alloys are very strong, even at high temperatures. This makes them ideal for use in spacecraft components that are subjected to high stresses, such as landing gear, engine components, and structural members.

Weight reduction

Magnesium is the lightest structural metal, making it idea for weight-sensitive. It is on average 75% lighter than steel, 50% lighter than titanium, and 33% lighter than aluminum reducing the weight of a spacecraft can save significant amounts of fuel, which is essential for deep space missions, environmental friendliness, and cost reduction.

Durability

Magnesium alloys are very durable and can withstand the harsh environment of space, including exposure to radiation, extreme temperatures, and vacuum.

Dimensional stability

Magnesium alloys have excellent dimensional stability, even at high temperatures. This makes them ideal for use in optical imaging devices and other precision instruments.

Magnesium alloys are used in a variety of spacecraft components due to their unique combination of lightness, strength of lightness, strength, durability, and dimensional stability.

Clusters

Magnesium alloys are used to make the clusters that house spacecraft electronics because they can dissipate heat well. Clusters are groups of electronic components that are packaged together to perform a specific function, such as processing data or controlling spacecraft systems. The heat generated by these components can damage them if it is not properly dissipated. Magnesium alloys are able to absorb and dissipate heat quickly, due to their good thermal conductivity, which helps to protect the electronic components in clusters.

Housings

Magnesium alloys are used to make the housings for spacecraft components, such as cameras, sensors, and actuators. These housings need to be strong and durable to protect the delicate components inside from the harsh environment of space. Magnesium alloys boast good strength to weight ratios, even at elevated temperatures.

Actuation systems

Magnesium alloys are used to make the actuation systems that control spacecraft movements. Actuation systems are responsible for moving the spacecraft’s solar panels, antennas, and other appendages. They also play a role in controlling the spacecraft’s attitude and orientation. Magnesium alloys are a good choice for this application because they are lightweight and can withstand high stresses.