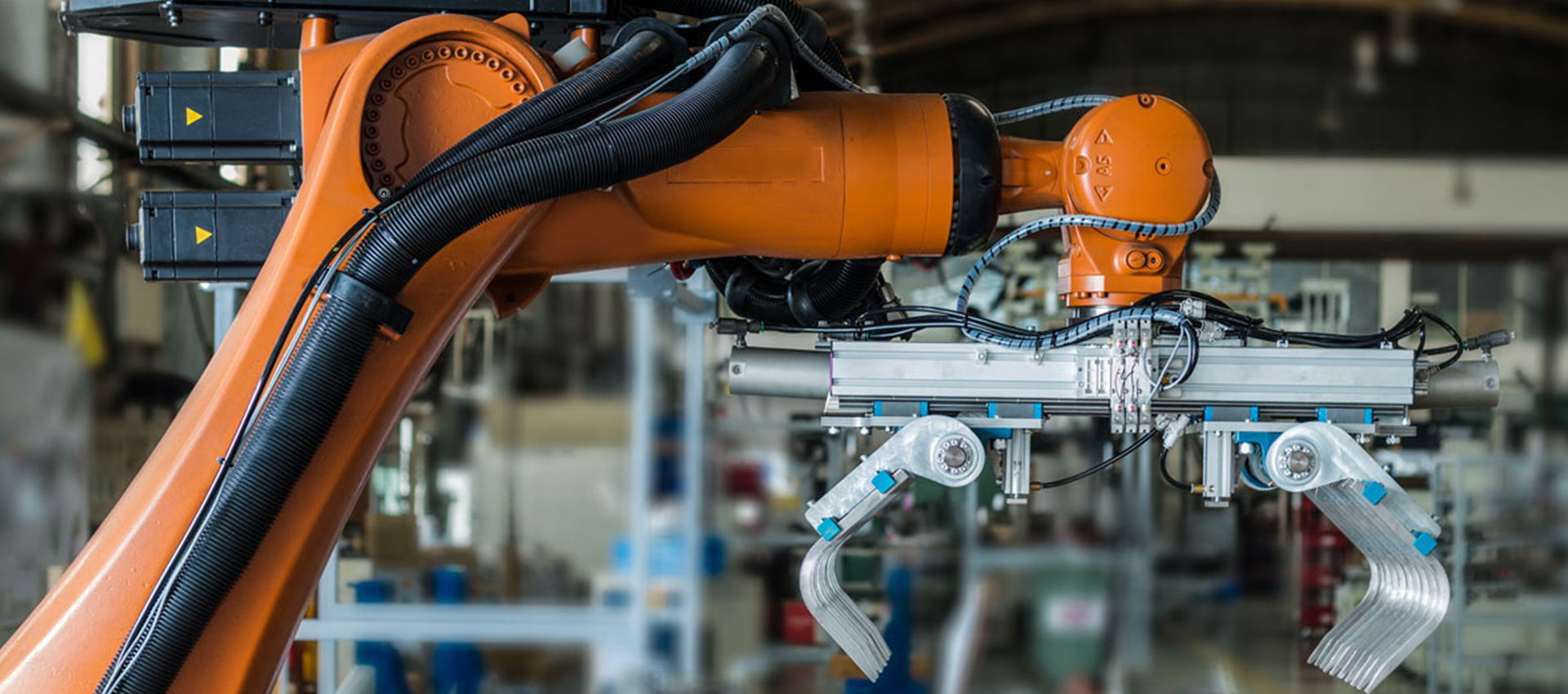

End of Arm Tooling (EOAT)

Magnesium is an ideal material for end-of-arm tooling (EOAT) due to its lightweight and strong properties.

It is the lightest structural metal and is significantly lighter than aluminum, steel, and titanium. This makes it ideal for EOAT applications where weight is a critical factor, such as pick-and-place robots.

Here are some of the benefits of using magnesium for EOAT:

Weight savings

Magnesium is up to 36% lighter than aluminum, which can lead to significant weight savings in EOAT. This can improve the speed and performance of robotic systems, as well as reduce the overall energy cost.

Improved collaborative safety

Magnesium’s lightweight properties make it ideal for collaborative robots, which are designed to work safely alongside humans. By reducing the weight of EOAT, collaborative robots can be made more agile and easier to control, reducing the risk of accidents.

Increased speed of automation

Magnesium’s lightweight properties also allow for faster acceleration and deceleration of robotic systems. This can lead to significant increases in the speed of automation, which can improve productivity and reduce costs.

Higher payload

Magnesium’s strength-to-weight ratio allows EOAT to be designed with higher payloads. This can be beneficial for applications such as palletizing and packaging, where robots need to be able to handle heavy loads.

Improved vibration damping

Magnesium has excellent vibration damping properties, which can help to improve the accuracy and precision of robotic systems. This is important for applications such as assembly and inspection, where robots need to be able to perform delicate tasks with high accuracy.

Reduced wear and tear

Magnesium’s lightweight properties can help to reduce wear and tear on robotic systems. This can lead to reduced maintenance costs and increased uptime.

Overall, magnesium is a versatile and valuable material for end-of-arm tooling. It offers a number of benefits, including weight savings, improved collaborative safety, increased speed of automation, higher payload, improved vibration damping, and reduced wear and tear.

If you are looking for a way to improve the performance and reliability of your robotic systems, consider using magnesium for end-of-arm tooling. Contact Luxfer MRP today to discuss your specific application and how magnesium can help you to achieve your goa